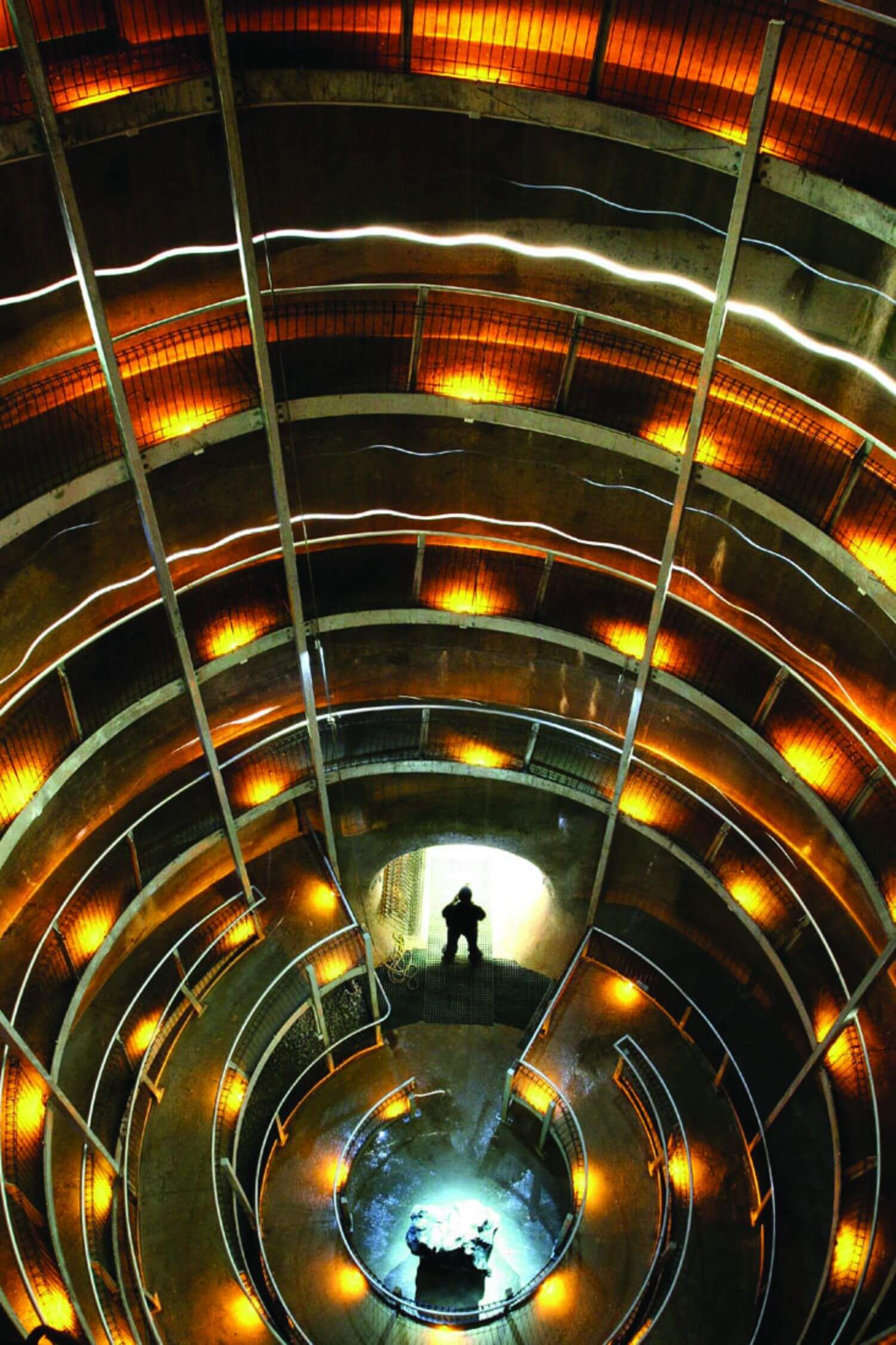

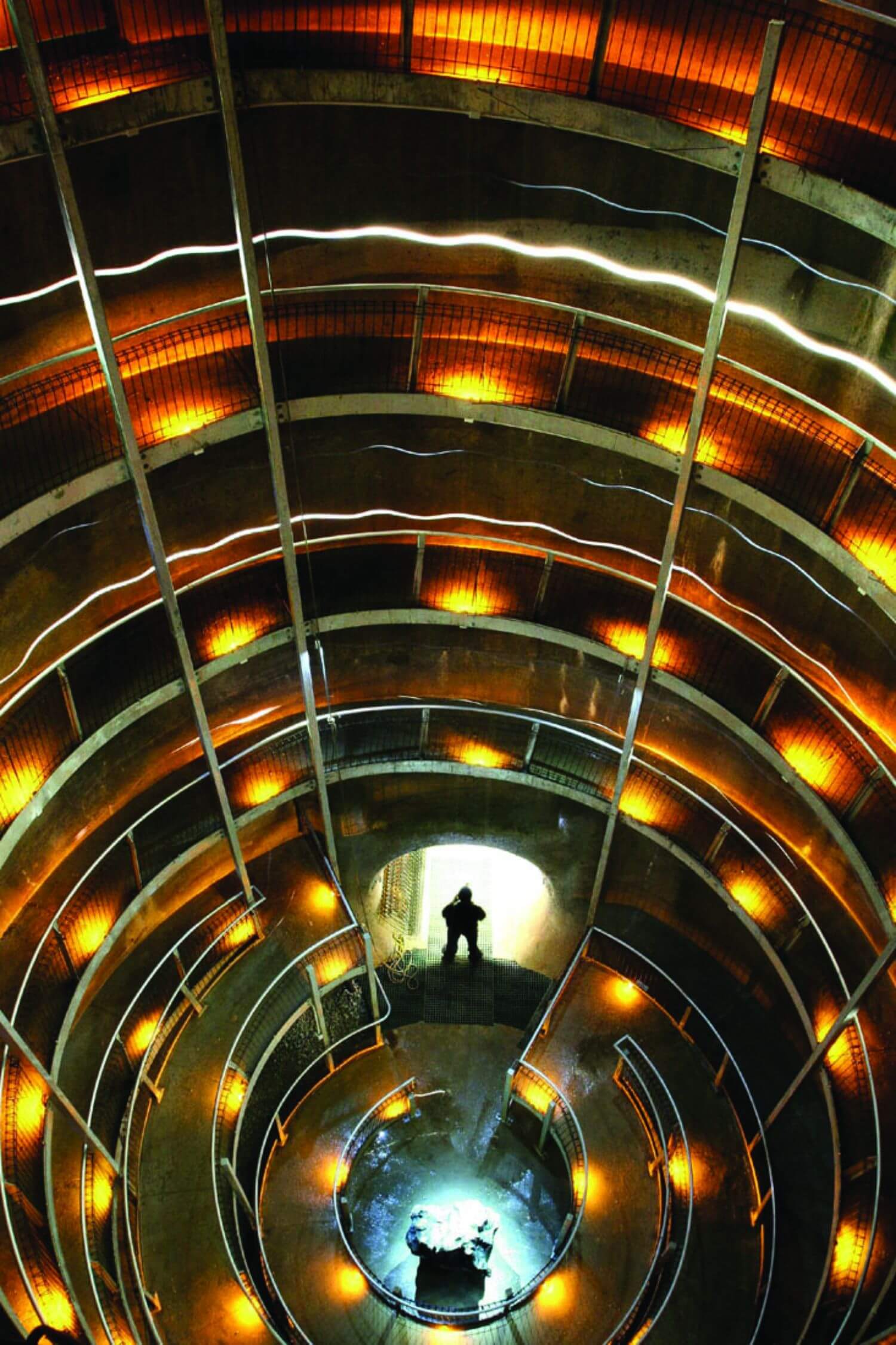

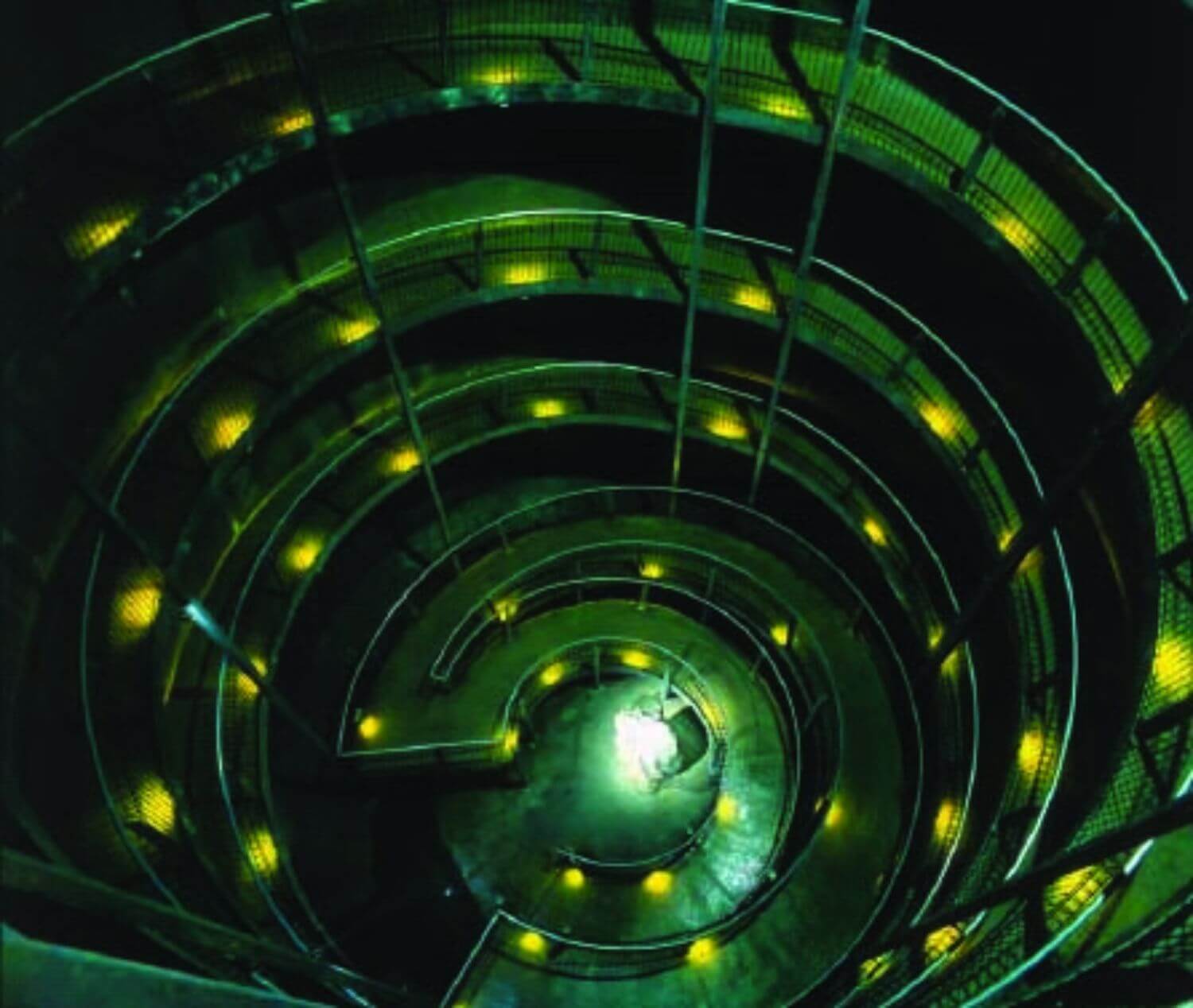

A new entrance shaft and tunnel into the cave was designed as a reinforced concrete shaft, 10 metres in diameter, extending 12 metres below ground level and with a 300mm thick wall. A 160 metre long suspended spiral walkway was designed to transport visitors up and down the shaft, creating an impressive ambient effect.

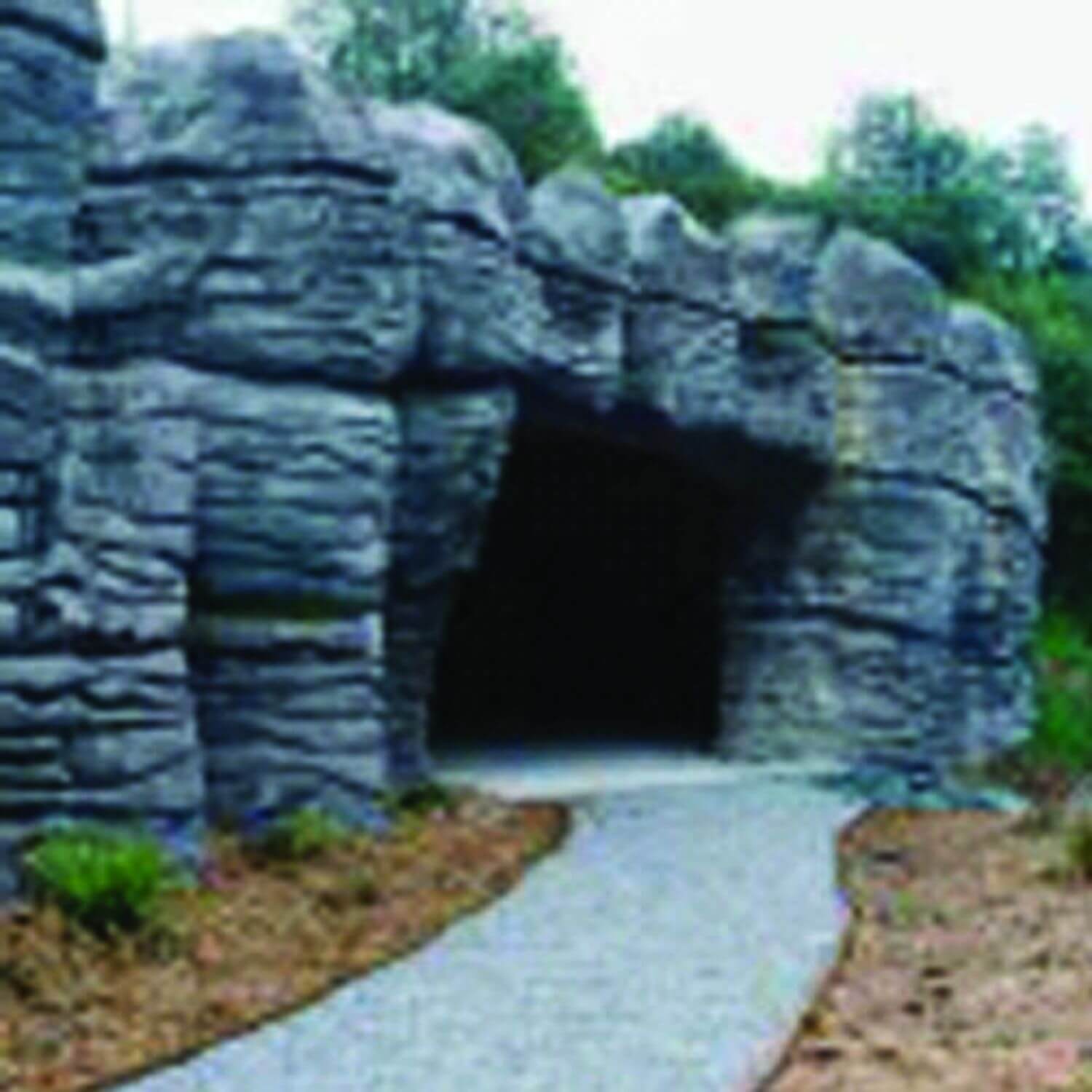

The cave system itself was hand- cleared of 300m3 of silt, with 500m of concrete paths and 100m of suspended walkways constructed throughout, all the while ensuring natural features were protected. The importance of keeping delicate stalactites undamaged whilst working in close proximity to them was an important priority for the Hawkins team.

Minimising the visual impact of the structures and getting workers and equipment in and out of the cave added to the challenges of this project. An existing flying fox was used to lower the more bulky items out over a sinkhole and down into the river, where workers were waiting to float them on rubber tubes into the cave.

The size and weight of these items was limited by the capacity of the flying fox and the ability to manhandle them into place. A 150mm diameter steel pipe extended some 65m from the ground into the cave was used to drop very small items and dry concrete mix into the cave.

With a guide from The Blackwater Rafting Company, workers had to float in rubber tubes to work wearing wet suits, change into dry clothes once in the cave and back into their wet suits and rubber tubes at the end of the day.

Environmental constraints were significant on the project. The Department of Conservation had set up monitoring stations, with stringent conditions relating to air temperature and humidity levels, so we could not use petrol tools, or do any blasting.

Environmental constraints were significant on the project. The Department of Conservation had set up monitoring stations, with stringent conditions relating to air temperature and humidity levels, so we could not use petrol tools, or do any blasting.

Conditions above ground were also strictly controlled to prevent damage to the reserve. All vehicles were refuelled off site, and were fitted with special pans to prevent any oil spills.

The project had numerous engineering and construction challenges, but the united sense of purpose that existed between the client, project consultants and Hawkins Construction meant that each obstacle was overcome and that construction was completed within a year.

The new visitor experience was formally opened in July 2005.